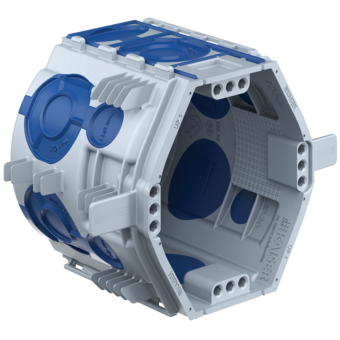

Universal installation housing

Universal installation housing

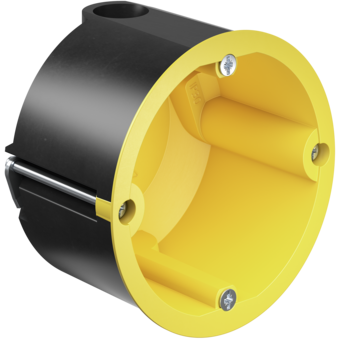

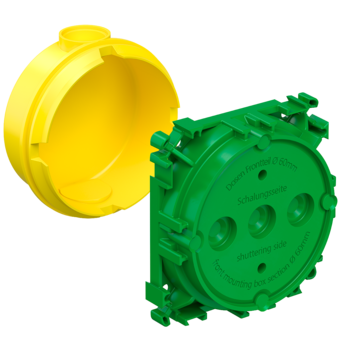

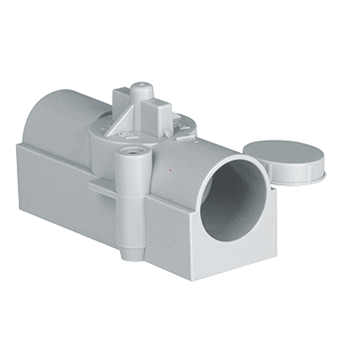

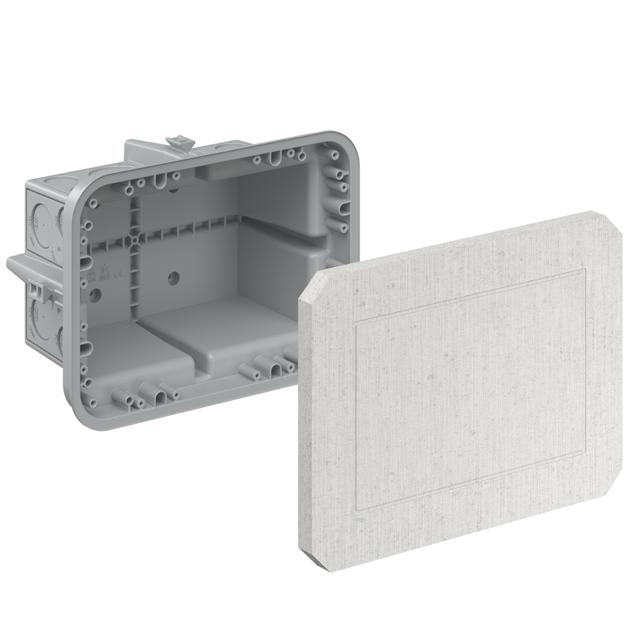

- Article no: 1298-37

- EAN: 4013456543812

- suitable for installation in horizontal or vertical formwork and in masonry

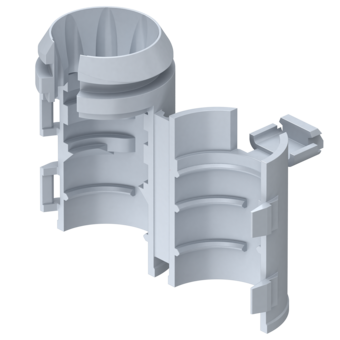

- two-part, consisting of a housing and a mineral fibreboard cover

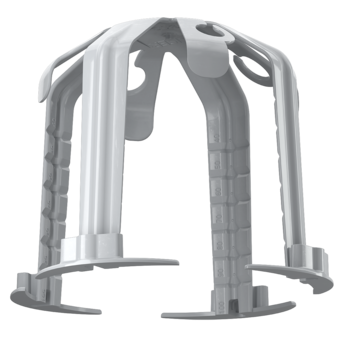

- Optional accessory: Set of Prefix® wing brackets

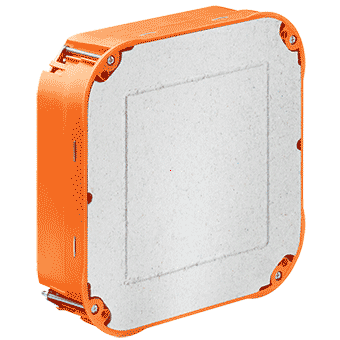

Universal installation housing

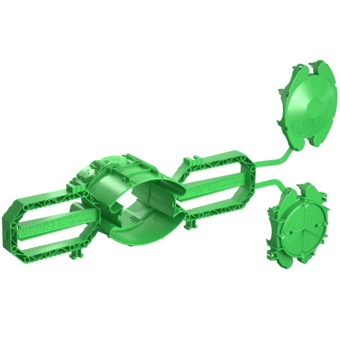

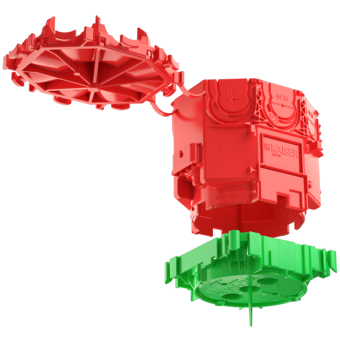

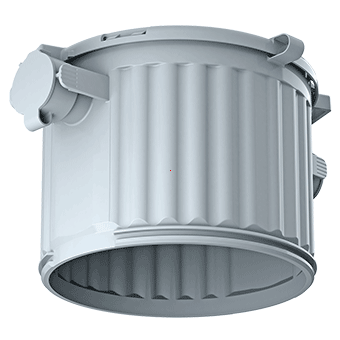

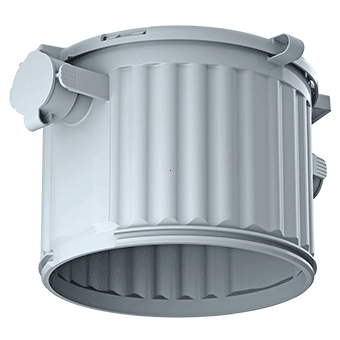

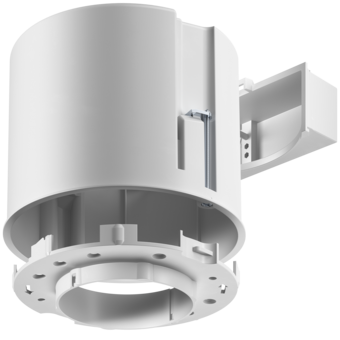

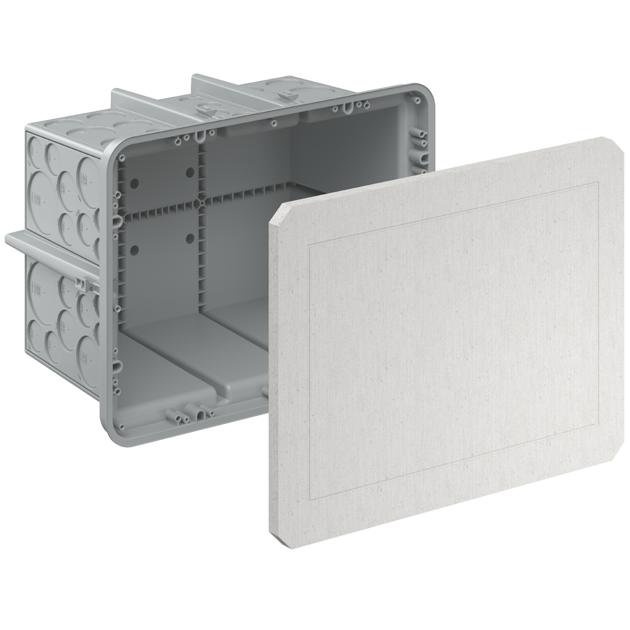

Universal installation housing for the installation of almost all device types and shapes in concrete walls and ceilings. The housing system consists of nine different installation housings and an extensive range of accessories.

- For displays, LED lights and much more

- For installing almost all shapes and sizes

- For installation in walls or ceilings

- For in-situ or prefabricated concrete

- For horizontal or vertical formwork and for masonry

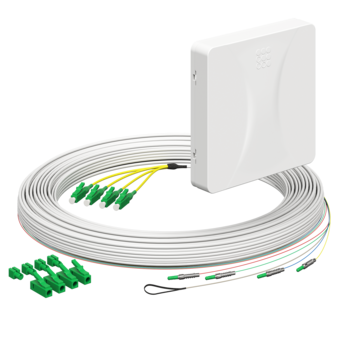

Application example

Note

The indicated wall thicknesses refer to walls without a fire protection function. The following applies to fire protection walls: Remaining wall thickness must be min. 60 mm. When using halogen lamps, pay attention to maximum power (see product details).

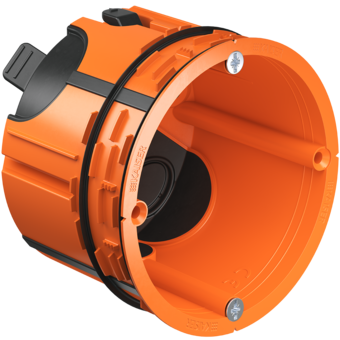

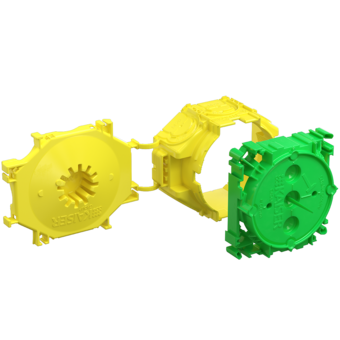

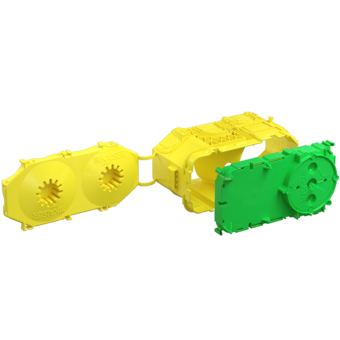

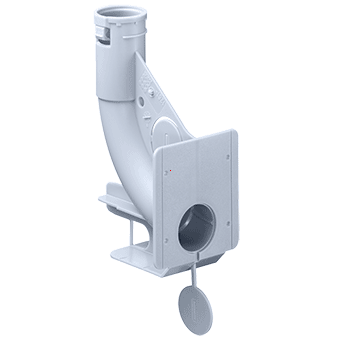

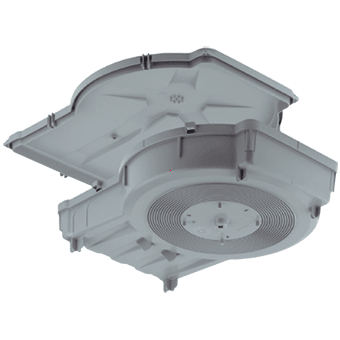

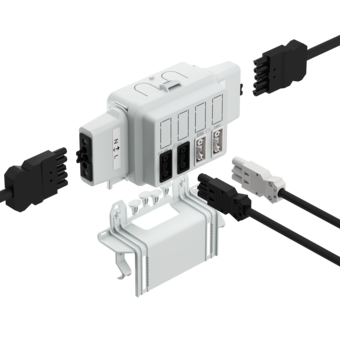

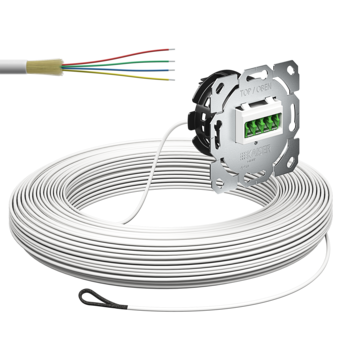

Support technology for boxes and installation housings

Supporting by means of telescopic support: Junction boxes and installation housings can be installed on either side of a wall after the formwork has been placed on one side - either by fixing them directly to the rear (already placed) formwork or by supporting them off the rear formwork via a telescopic support. If the junction box is attached directly to the already-placed formwork or if heavy loading is to be expected due to a large concrete pouring height, additional securing by means of a telescopic support is recommended.

1 Working formwork | 2 Opposing formwork | 3 Base plate | 4 Supporting plate | 5 Junction casing | 6 Hose clamp | 7 Wall thickness +2 cm | 8 Nail

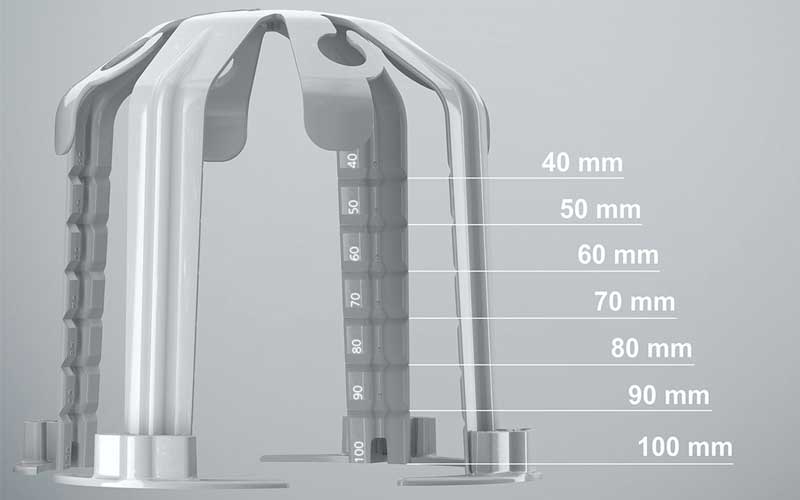

Adjusting the telescopic support to different wall thicknesses

Note

When the formwork is closed, the junction box and the telescopic support are compressed between the formwork panels. The extra 2 cm of length allowed ensures sufficient pressure for a secure fit. Always tighten the hose clamp fully!