Abutment and support elements

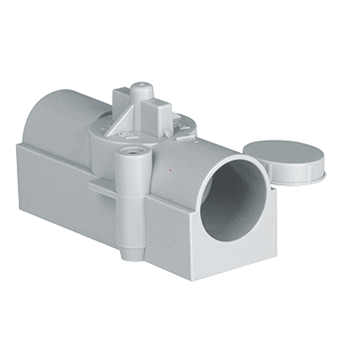

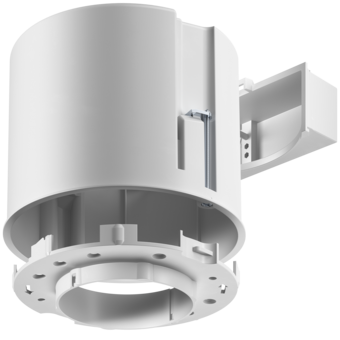

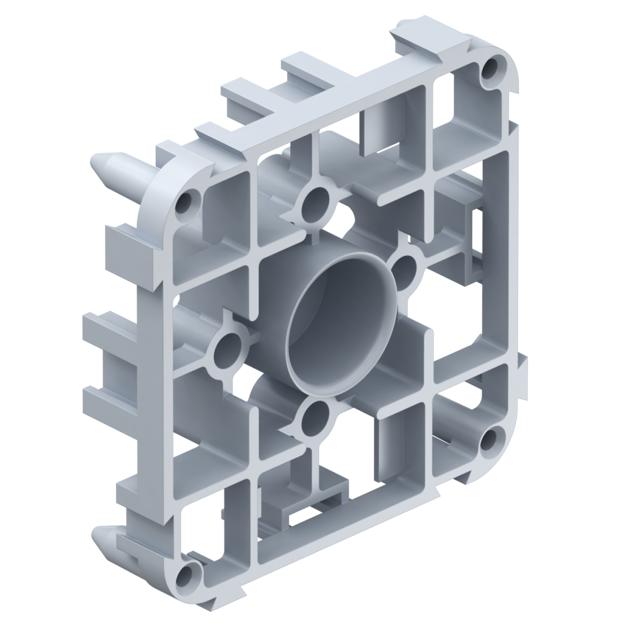

Abutment

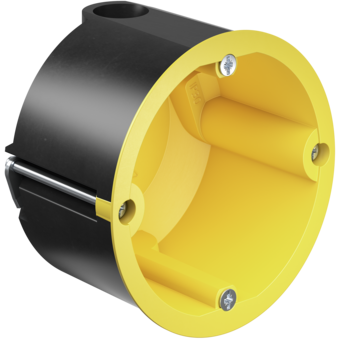

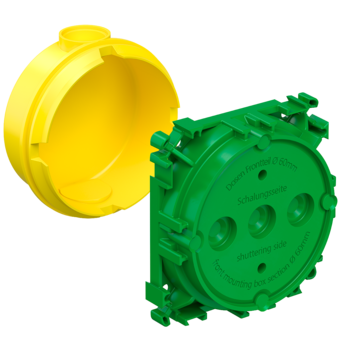

Abutment

- Article no: 1210-02

- EAN: 4013456351202

- for support element Ø 20 mm

- can be combined with itself, with one-gang boxes, one-gang junction boxes, junction casing, universal installation housings and distance pieces 91

- Fixing to the formwork using expanding dowels, nails or screws

Dispatch

250

Product information

Abutment and support elements

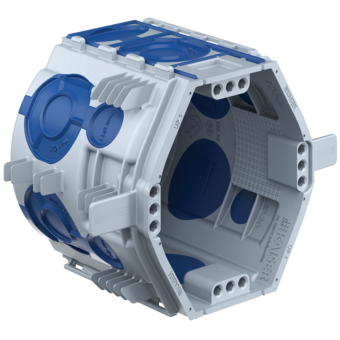

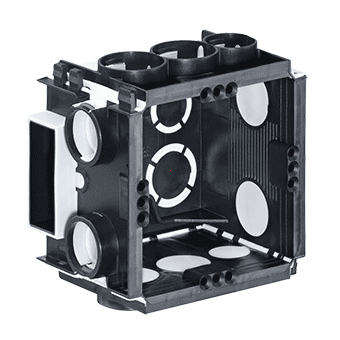

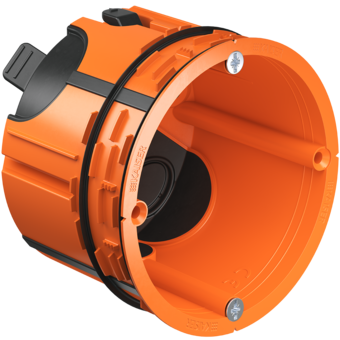

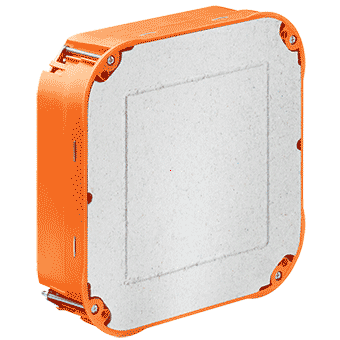

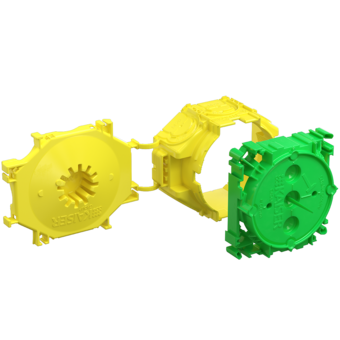

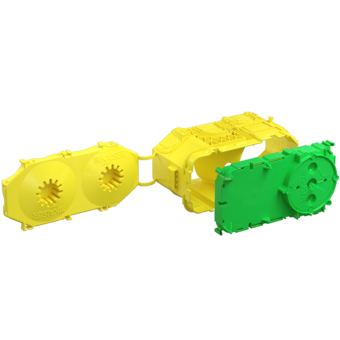

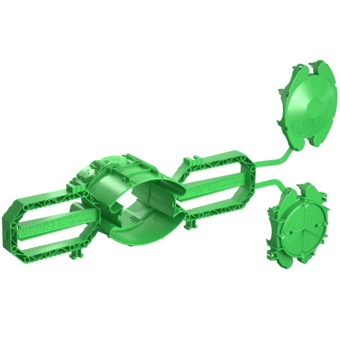

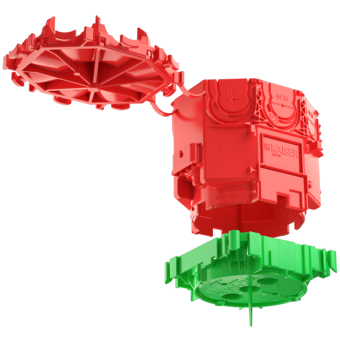

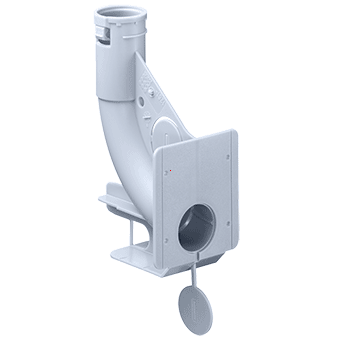

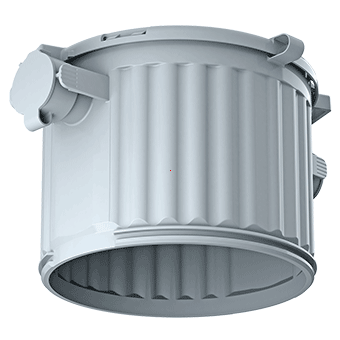

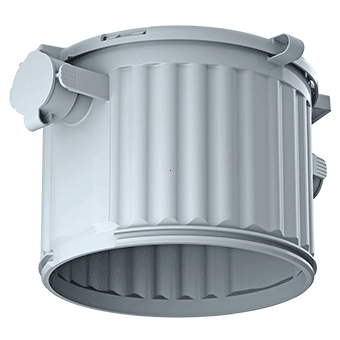

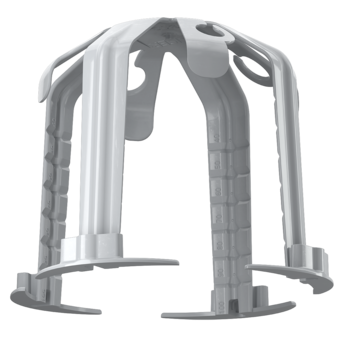

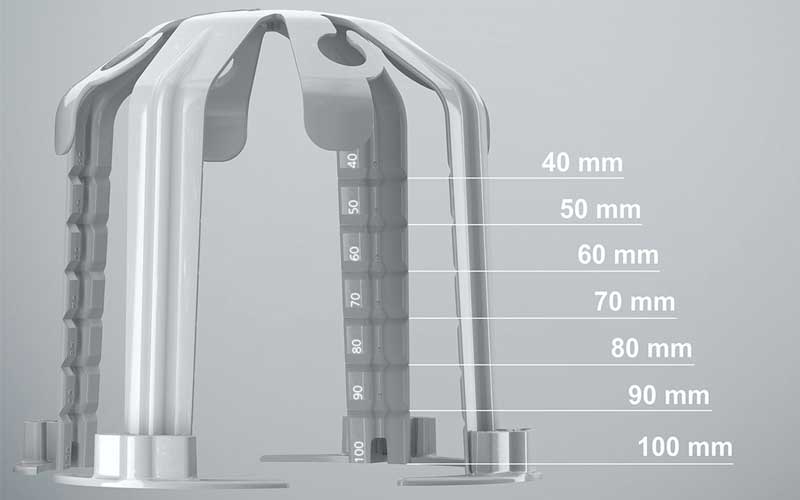

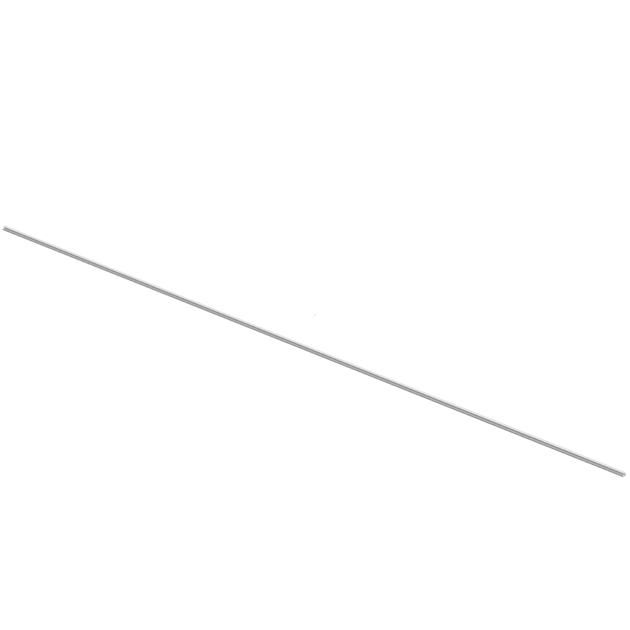

The on-site mixed concrete programme offers special abutments and support elements for the installation of opposing one-gang boxes or the installation of one-gang boxes and junction casings on the opposite side of the formwork. For this purpose, there are holders in the back of the item that provide the support elements with a anti-rotation hold. The curved base of the box facing outwards forms an integrated spring travel, which is used to compensate for component-related tolerances when setting the opposing formwork by compressing it.

- Two abutments for fixing to the working formwork using expanding dowels, nails, screws or adhesive foil

- No blocking of conduit entries thanks to the anti-rotation support element attachments in the back of the one-gang boxes and junction casings

- The integrated spring travel ensures a secure hold between the working and opposing formwork and compensates for construction tolerances

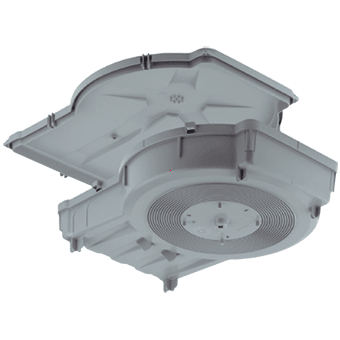

- Thanks to their star-shaped contour, the support elements ensure that the concrete flows around the entire surface

Calculation for the supporting elements

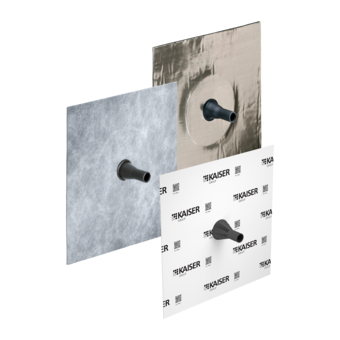

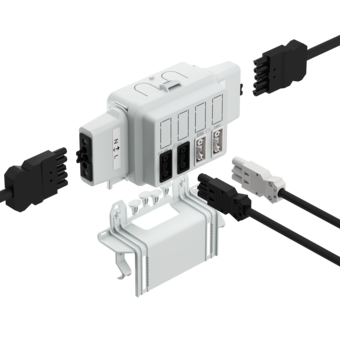

Installation to the opposing formwork side by means of a support element

Download

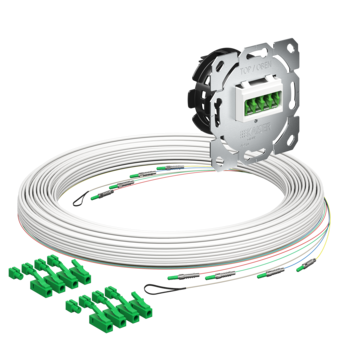

Accessories

Product recommendations

Planning