Notice! Our recommended retail prices for Germany are intended exclusively for business customers (electrical wholesalers and trade) in Germany. All prices are net prices and apply plus VAT.

-

Overview

-

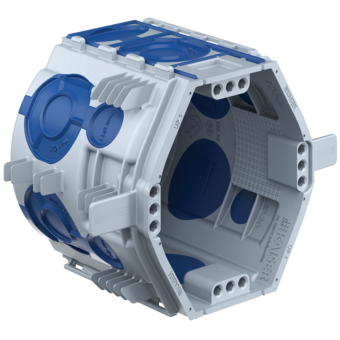

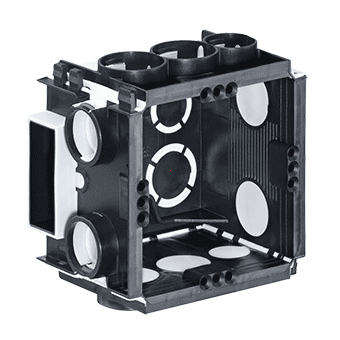

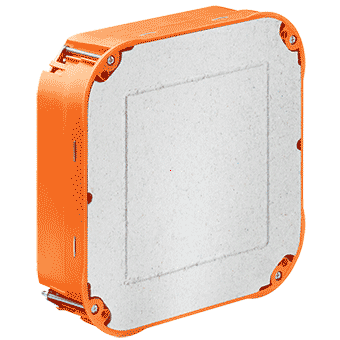

UP¹ flush-mounting boxes

-

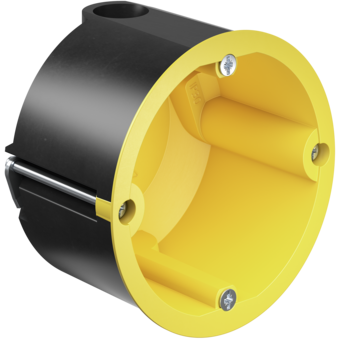

One-gang boxes, One-gang junction boxes

-

Junction boxes

-

Light connection boxes, Ceiling exits

-

Screened electrical installation

-

Accessories

-

Junction casings

-

Universal installation housings

-

Installation systems for insulated interior walls

-

Installation systems for insulated exterior facades

-

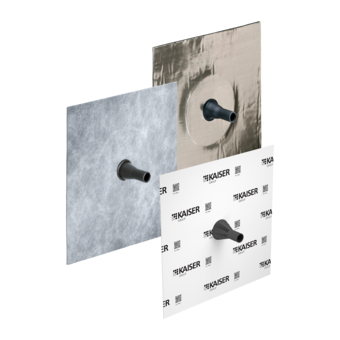

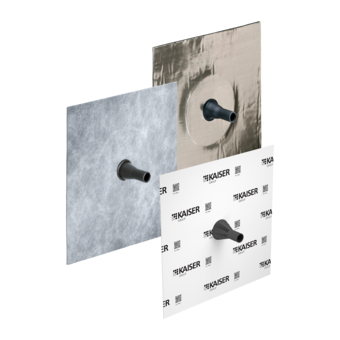

Sealing sleeves

-

Fire protection technology

-

Sound insulation technology

-

International products

-

-

Overview

-

One-gang boxes, one-gang junction boxes, accessories

-

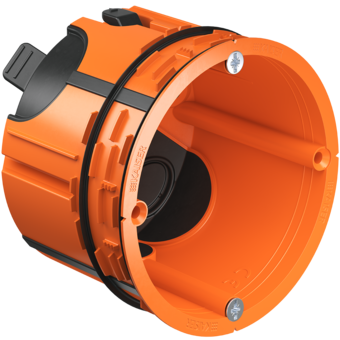

Air-tight one-gang boxes, one-gang junction boxes, accessories

-

Installation in solid wood walls

-

Sealing sleeves

-

Clean room technology

-

Sound insulation technology

-

Radiation protection

-

Fire protection technology

-

Screened electrical installation

-

Waterproof technology

-

Screws, Metal lugs

-

Junction casings

-

Universal installation housings

-

International products

-

-

Overview

-

B¹ One-gang boxes, B¹ One-gang junction boxes

-

B¹ Electronics box and B¹ two-gang junction box

-

One-gang boxes, One-gang junction boxes

-

Junction casings and accessories

-

Prefix® concrete construction box for attaching to the reinforcement

-

B¹ Ceiling boxes and accessories

-

Wall-ceiling transitions, ceiling strips, conduit supports, sealing plugs

-

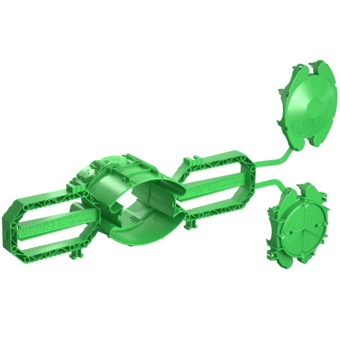

Wire-pull casings

-

Universal installation housings

-

International products

-

End covers and separator walls

-

Accessories

-

-

Overview

-

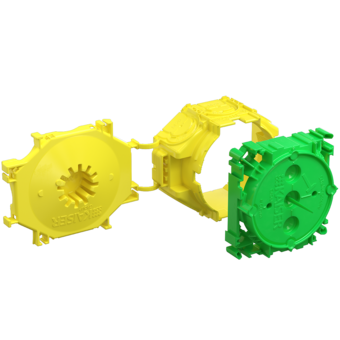

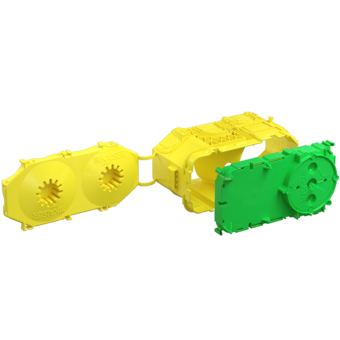

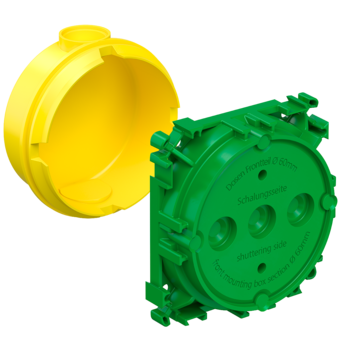

Automated prefabrication - B² One-gang junction boxes and system components

-

Manual prefabrication - B² One-gang junction boxes and system components

-

Prefabricated room modules - The system for prefabricated concrete garages and prefabricated concrete bathrooms

-

Accessories

-

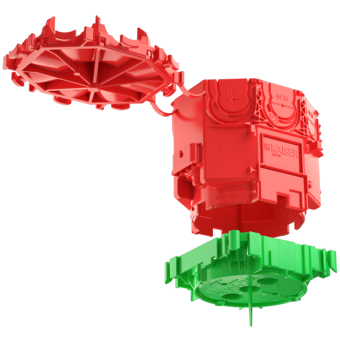

Central transition casing

-

Universal installation housings

-

International products

-

-

Overview

-

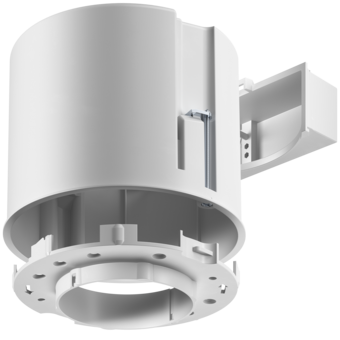

System HaloX® for on-site mixed concrete

-

HaloX® system retrofitting in concrete ceilings

-

HaloX® system overview for precast concrete

-

KompaX®1 system for on-site mixed concrete and precast concrete

-

KompaX®2 system for on-site mixed concrete and precast concrete

-

KompaX® accessories

-

System ThermoX® for insulated hollow ceilings

-

System EnoX® for insulated hollow ceilings and cavity walls

-

System ThermoX® LED for insulated hollow ceilings

-

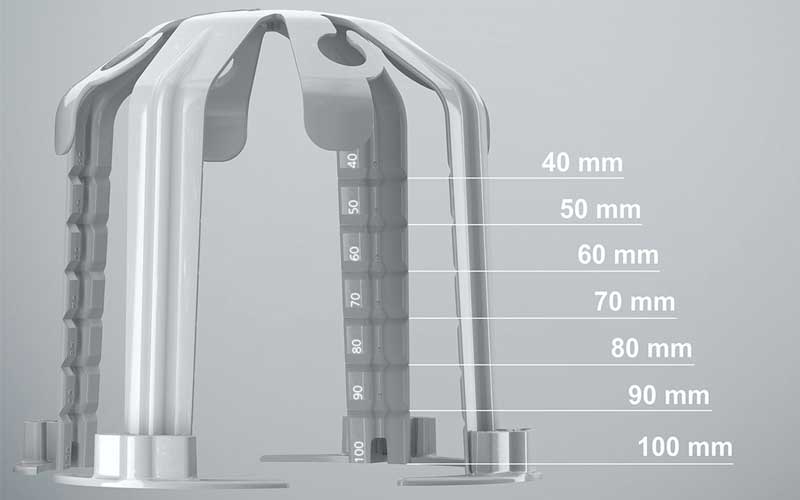

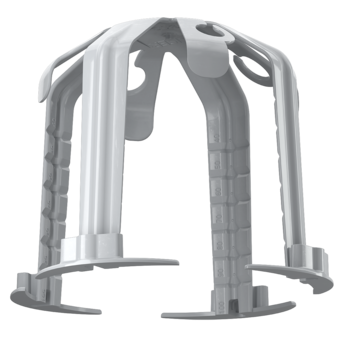

Spacer

-

Installation systems for insulated exterior facades

-

-

Overview

-

Fire-protection boxes

-

Installation in solid wood walls

-

Sealing systems in shipbuilding walls and ceilings B15

-

Sealing systems in fire-protection walls

-

Sealings in fire-protection ceilings

-

Accessories for sealings

-

FlamoX® system for hollow ceilings - fire protection class F30

-

International products

-

-

Overview

-

EVolution EMC cable Glands

-

Progress® nickel-plated brass

-

Progress® stainless steel

-

Special cable entries, nickel-platted brass

-

Progress® EMC nickel-plated brass

-

Ex cable glands

-

Cable glands Progress® AgreenO nickel-plated brass lead-free

-

Conduit gland Progress® nickel-platted brass

-

Progress® FGR synthetic

-

Syntec® with lamellar technology

-

Special cable entries, synthetic

-

-

Overview

-

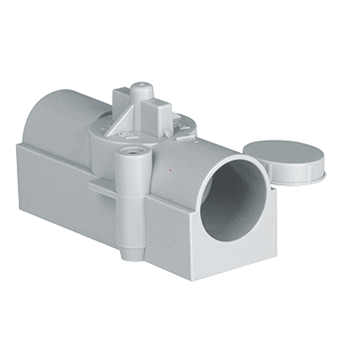

Supply sleeve

-

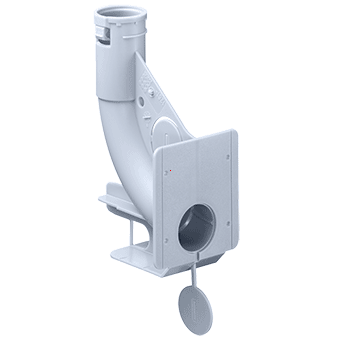

Shaft sleeve holder for Fibre Management Plate (FMP) incl. wall bracket

-

Splice distributor box (FMP)

-

Splice cassette

-

Hood sleeve (MFD)

-

Repair sleeve (CFD)

-

Mains distributor (Gf-NVt) - glass fibre reinforced plastic (GRP)

-

Mains distributor (Gf-NVt) with FMB - glass fibre reinforced plastic (GRP)

-

Mains distributor (Gf-NVt) with FMB - Metal

-

Fibre termination unit (FTU)

-

House transfer point (HTP)

-

House transfer point (HTP), shutter, ready to splice

-

-

Overview

-

Building distributor (Gf-GV)

-

Compact building distributor (Gf-GV)

-

Connecting sleeve

-

Optical termination outlet (OTO), surface-mounted

-

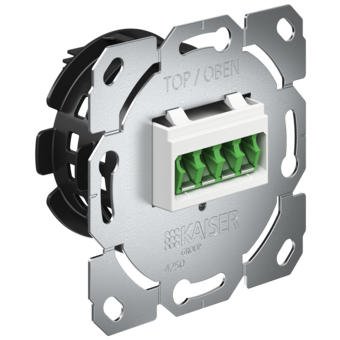

Optical termination outlet (OTO), flush-mounting

-

Optical termination outlet (OTO), surface-mounted with cable, backside

-

Optical termination outlet (OTO), surface-mounted with cable, bottom

-

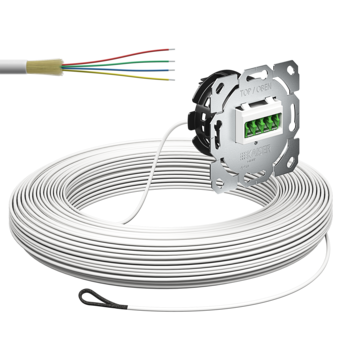

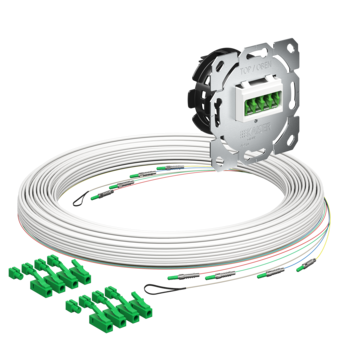

Optical termination outlet (OTO), flush-mounting with cable, backside

-

Accessories

-

-

Overview

-

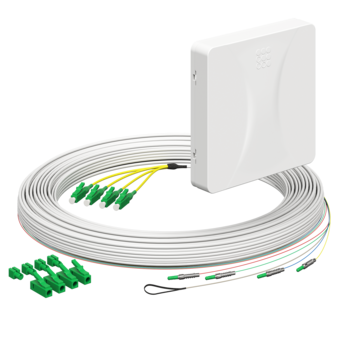

Optical telecom outlet (OTO) E3S Connect®, surface-mounted, connection to the BEP

-

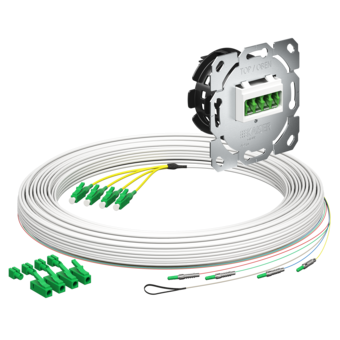

Optical telecom outlet (OTO) E3S Connect®, flush-mounting, connection to the BEP

-

Optical telecom outlet (OTO) E3S Connect®, surface-mounted, connection to the FMB

-

Optical telecom outlet (OTO) E3S Connect®, flush-mounting, connection to the FMB

-

Fibre optic patch cord E3S Connect®

-

System cable E3S Connect®

-

Building distributor E3S Connect®

-

Patch cassette E3S Connect®

-

E3S Connect® accessory box

-

-

Overview

-

UP¹ Flush-mounting boxes

-

Fire-protection box HWD 68+

-

Trilo - the new generation of cutters

-

One-gang junction box for solid wood

-

Damp room one-gang junction box

-

One-gang junction box for solid wood fire protection PROTECT®

-

Clean room one-gang junction box

-

B² Precast concrete

-

System Flat 45 - Electrical installation in concrete room module production

-

Marine

-

-

Overview

-

Solutions for installation at the shipyard

-

Solutions for installation in cabin construction

-

Electrical installation in fire protection ceilings and walls

-

Electrical installation in furniture and walls without protection class

-

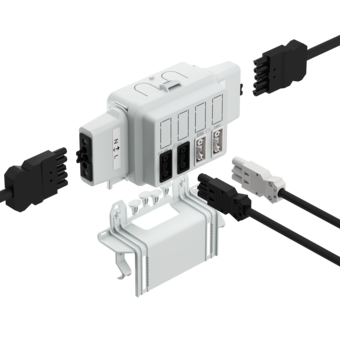

Pluggable Installation

-

The AGRO AG - Industrial solutions at the shipyard

-

We use cookies. Some of them are technically necessary (for example for the shopping cart), others help us improve our website and to offer you a better user experience. To our data protection regulations.

You accept the following cookies by clicking on Accept all. You will find further information in the privacy settings, where you can also change your selection at any time. Just go to the page with the privacy policy.

Technically necessary cookies enable a website to store information that has already been entered (such as user name or language selection) and to offer the user improved, more personalised functions.