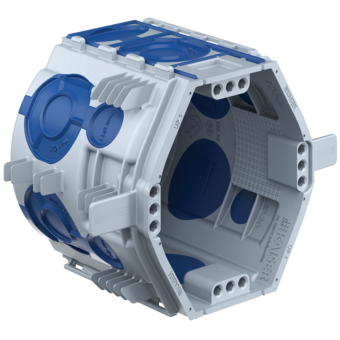

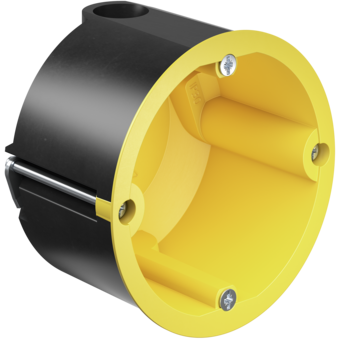

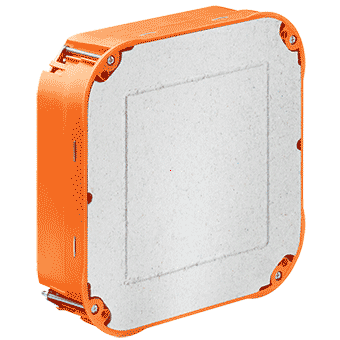

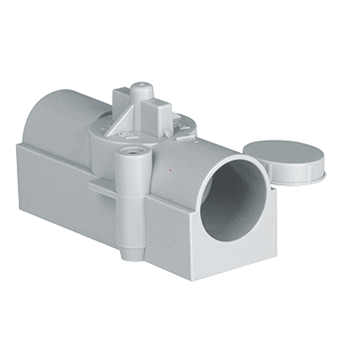

HWD 90 cavity wall boxes

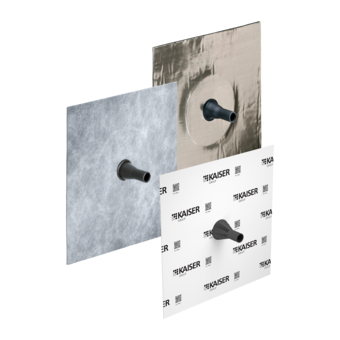

FlamoX® fire-protection putty

- Article no: 9400-05

- EAN: 4013456461611

- Building material forming an insulating layer

- for filling joints as well as bonding board materials

- Type 9400

- Working time 30 mins.

- Can be stored up to 12 months

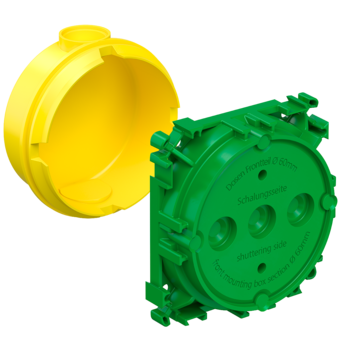

HWD 90 cavity wall boxes

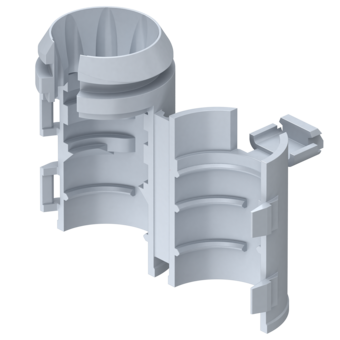

HWD 90 cavity wall boxes for F30-F120 or EI30-EI120 fire-protection walls ensure certified and fire-protection compliant electrical installation. They are now also approved for timber walls in F30-B/F60-B timber frame or timber panel construction. No additional measures, such as encasing, are necessary. The intelligent AFS technology reacts immediately to fire and heat and automatically closes the installation opening. This guarantees the fire resistance class of the fire-protection wall and secures emergency routes. Use in all fire-protection walls and the fire-resistance duration of up to 120 minutes ensures maximum flexibility, even when the planning is changed. At the same time, it also maintains the wall's sound insulation requirements.

- For F30-F120 or EI30-EI120 and F30-B / F60-B fire-protection walls

- Maintains the wall's sound insulation protection

- Retrofitting also possible

- With fire-protection cover, can be used as a junction box

- Also for directly opposing installation

- DIBt approval Z-19.11-1583

Processing instructions

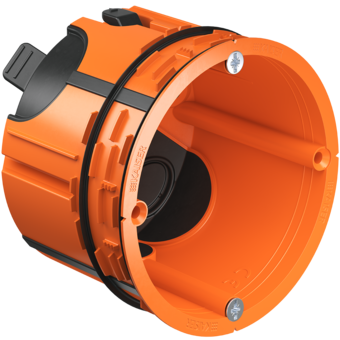

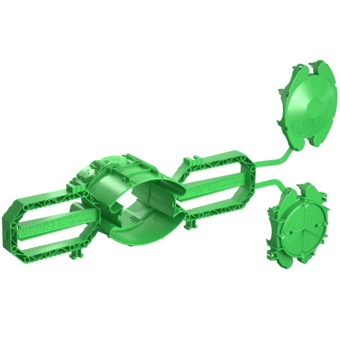

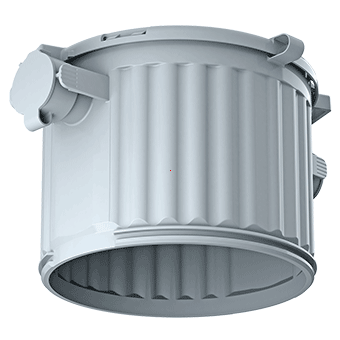

For drywall in timber construction

Since the introduction of the first fire-protection box for fire-protection walls in 2006, the range of applications has been continually expanded. HWD 90 fire-protection boxes are now also approved for timber walls in timber frame or timber panel construction. They maintain the fire protection properties of the wall with a fire-resistance duration of F30-B and F60-B. No additional measures, such as encasing, are necessary. Even if installed on the directly opposing side, the fire protection of the wall is guaranteed for 30 minutes and 60 minutes. It should be noted that for F60-B, only superstructures and installations in accordance with the timber construction guidelines are currently permitted. The HWD 90 was tested in different superstructures that occur in practice to the superstructures and installation situation described in the timber construction guidelines.

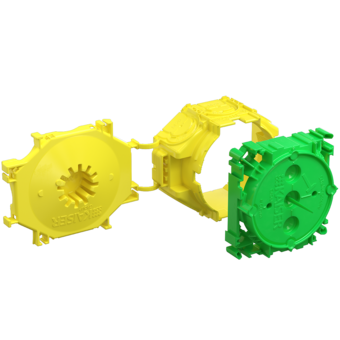

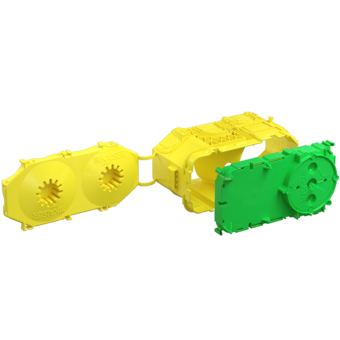

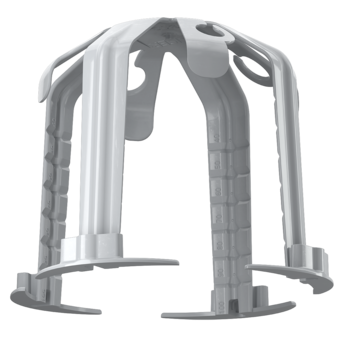

Drywall in timber construction

The proven installation has not changed. Installations directly opposing each other are possible even in timber construction up to fire resistance class F30-B (max. 5-way combination) or F60-B (max. 3-way combination). All HWD 90 type boxes maintain the sound insulation function completely up to a sound insulation level of 77 dB.

1 9.5 mm plasterboard | 2 15 mm OSB/MDF, plywood or chipboard | 3 40 mm wood fibre insulation, glass or rock wool 60x40 wooden beams | 4 1x12.5 mm plasterboard fire protection board | 5 80 mm mineral insulation > 1,000°C - 40x80 wooden beams

Note

All technical specifications correspond to the tested and approved applications. Technical deviations or changes are possible in the approvals and must be checked before use.

Installation

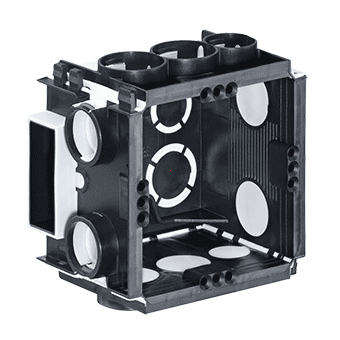

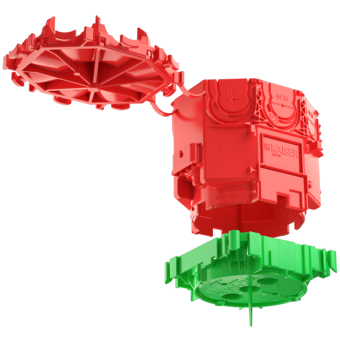

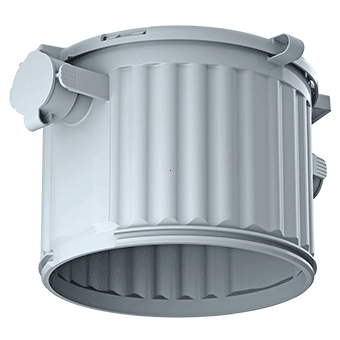

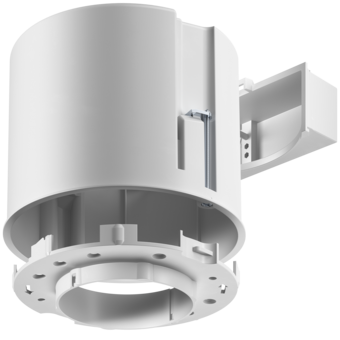

Plasterboard drywall

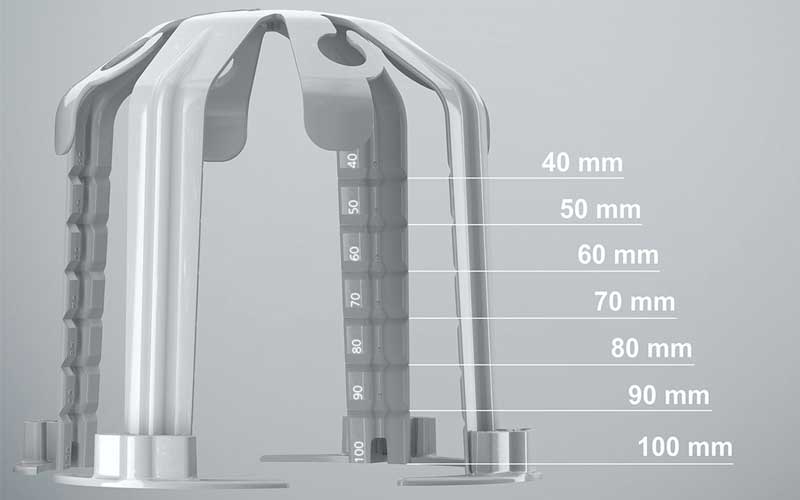

Minimum wall thickness: 100 mm | boarding on both sides with | min. 12.5 mm mineral non-combustible building panels (e.g. plasterboard, cement-bonded fibre boards) | min. 40 mm thick non-combustible mineral wool (e.g. glass wool, rock wool, etc) | gross density min. 14 kg/m³

Installation shafts and ducts

The use of the HWD 90 in shaft walls is only approved in Germany by the general type approval. If the device is to be used in other countries, the applicable certificates, standards, guidelines or regulations must be observed. Steel stand | double boarding with non-combustible mineral plaster or cement-bound building panels | 2 x 20 mm (when using the one-gang box) | 2 x 25 mm (when using the one-gang junction box) | I30 - no insulation | I60 - 40 mm / 100 kg/m³, 60 mm / 50 kg/m³, 80 mm / 30 kg/m³ | I90 - 40 mm / 100 kg/m³ Termarock 100

Note

In addition to the general type approval from the DIBt, we can also provide you on request with the classification report on its recognition in Austria from the IBS Test Institute for Fire Protection Technology and Safety Research in Linz. Please note: the use of the HWD 90 in shaft walls is only permitted in Germany by the general type approval. If the device is likely to be used in other countries, the applicable certificates, standards, guidelines or regulations must be observed.

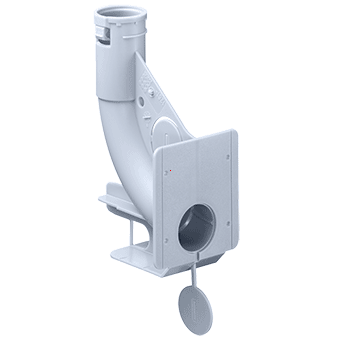

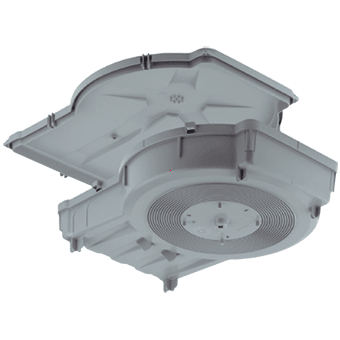

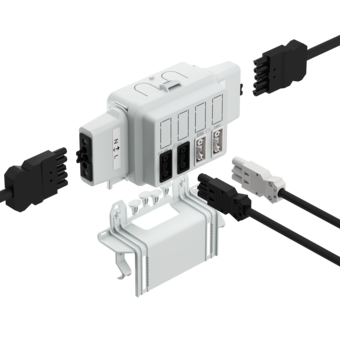

Retrofitting in installation shafts

The HWD 90 cavity wall boxes can also be retrofitted in installation shafts (shaft walls). Since retrofitting partly requires adding mineral wool to the opening, a cut-out of at least 300 x 300 mm is needed to make space for perfect installation. Use the following cut-out dimensions for the relevant combinations:

- 1-time: 300 x 300 mm

- 2 to 3-times: 300 x 400 mm

- 4 to 5 times: 300 x 600 mm